We are proud to introduce our latest measurement room, specified to VDI 2627 Class 3 standards, offering the highest standards for precision measurements. Our goal is to create optimal conditions for accurate results through advanced technology and strict environmental controls.

Unique Features of Our Measurement Room:

Environmental Control and Monitoring:

We use two different measuring machines so that we can best fulfil our customers’ requests and requirements for measuring laminations, and so that we can check the dimensional accuracy of our own cutting performance. With the measuring machine from Keyence (DXF contour comparisons / tolerance band), we measure your sheets in detail if required and send you the corresponding measurement reports. Below you will find some key data for our 2D measuring machines.

KEYENCE IM-7030T

Key data

Chotest VX8300

.jpg)

Key data

Werth FB DZ 100

Key data

The measurement logs are saved in the form of a pdf file.

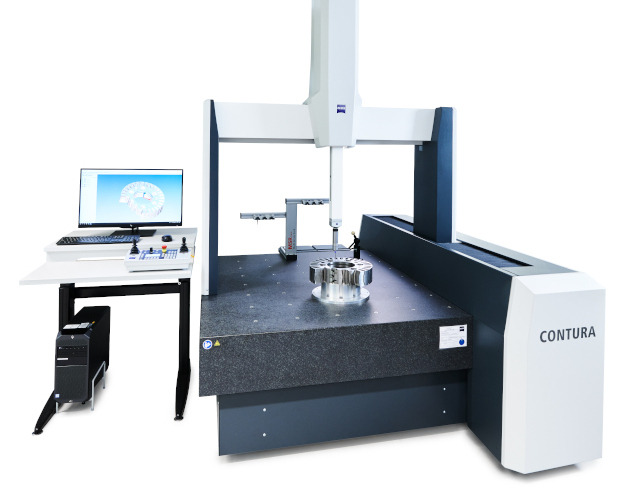

We have opted for Zeiss machines as the best option to fulfil our customers’ requests and requirements for measuring lamination stacks. These provide us with the best potential to cover a broad spectrum. A selection of the key details for our two 3D measuring machines is listed below.

Zeiss DuraMax

Key data

Zeiss Contura

Key data

Zeiss Contura

Key data

The measurement logs are saved in the form of a pdf file PDF or Excel file.