We have equipped our quality department with new measuring machines so that we can deal with the fast-growing movement towards quality control. One additional important aspect of measurement is the traceability this guarantees.

We interpret quality holistically, positioning it at the centre of our customers’ and partners’ business processes

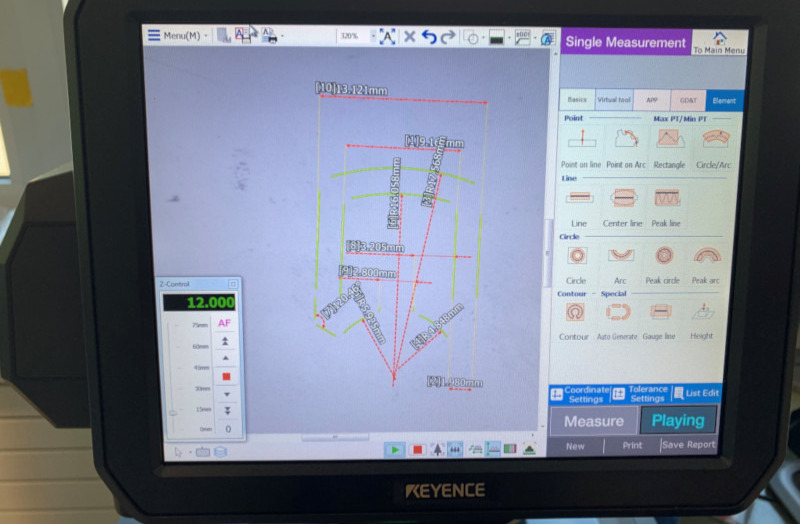

We are able to check and measure cut laminations with 2D measuring machines and profile projectors.

Key data

We measure in accordance with the requirements of the current GPS standards.

On request, we can also offer series measurements on components that we ourselves have manufactured

Further details of the measurement machines are available under the “Technology” menu item

We aim to cover as broad a range of our customers’ wishes as possible, so we work with two different measurement machines. Both come from Zeiss and are designed for stacks of varying sizes.

Key data

On request, we can also offer series measurements on components that we ourselves have manufactured

Further details of the measurement machines are available under the “Technology” menu item.

On request, or following consultation, we also produce test gauges. The measurements can be entered into a 3D test log.

Of course, we also offer manual measurements. Calliper measurements up to a diameter of 2000mm, micrometer measurements to a maximum diameter of 400mm and height measurements with a Micro-Hite up to 450mm.

In future, we will also be offering electrical measurements