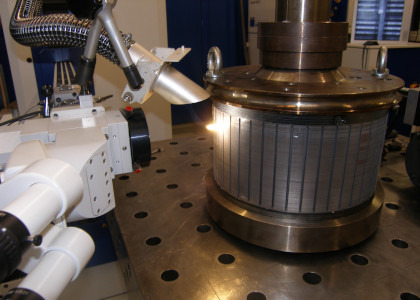

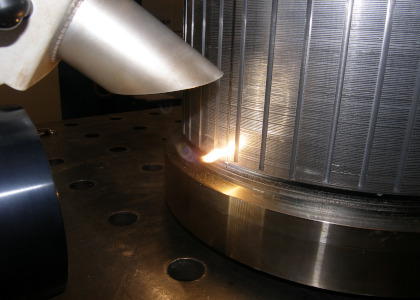

The laser welding process involves no additional fillers, i.e. it needs no welding rods or other materials to weld the steel sheets together. A laser is used to deliver the required energy. This process is mainly used to weld lamination stacks that require a fast welding speed, a narrow, lean shape of weld seam and low level of thermal distortion.

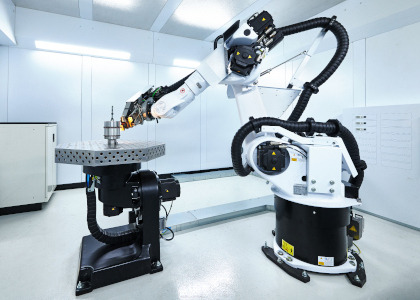

This is a system for the automatic laser welding of stacks of electrical steel laminations. The tilt & turn manipulator makes it possible to weld even hard-to-reach stacks in a single set-up. In order to manufacture your stacks economically in higher volumes, we can prepare the next stack on the two-station turntable while a stack that has been set up previously is still being welded in the safety enclosure.

This facility also makes it possible for us to weld high silicon materials that are not normally weldable, by adding a welding wire.