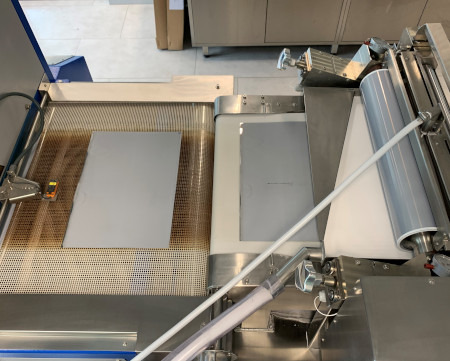

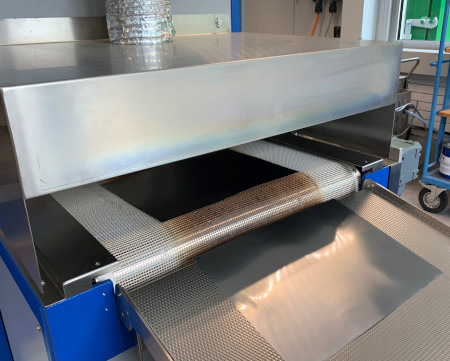

The demands made upon electric motors continue to increase, and can often only be met by using special materials. This trend has grown significantly over the past few years, and we have therefore developed and installed our own coating facility for bonding varnish. This enables us to coat almost all the different grades of electrical steel sheet, and thus manufacture stacks that are extremely precise and robust. For example, thick end plates made of steel can be directly bonded onto a cobalt iron lamination stack, which removes the need for the weld seams that would otherwise be necessary. This, in turn, has a direct effect on the performance of the motor.

Benefits

Properties

High adhesive strength

Link von Video auf Youtube produced by PB